The German Federal Ministry of Education and Research (BMBF) funding programme “Innovative Regional Growth Cores” is effectively using the competences and potentials available in eastern Germany and further developing them. The technology platform “Virtual Product and Process Development and Optimisation” (VIPO) is also being promoted as an innovative regional growth core. In addition to ORISA, eight other cooperation partners are researching digital processes, procedures and methods for the optimisation of product life cycles.

All important information on the service life of a machine is provided almost in real time

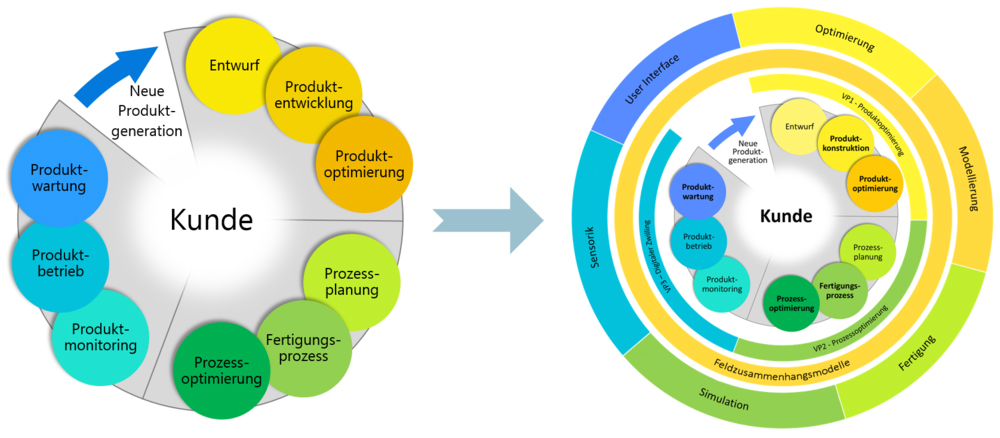

VIPO’s software specialists and engineers are optimising products and their manufacture. With computer simulations precisely matched to the machines, they enable predictive maintenance of machines. The goal is to implement virtual product and process optimisation along the entire value creation cycle as early as possible. The optimal design of the components can be found and the lifetime of the machine in use can be predicted continuously. The VIPO Alliance with its technology platforms supports small and medium-sized enterprises without their own research departments and IT specialists. In order to put their technologies into practice, the growth core partners based in the state of Thuringia are constructing three demonstrators: These are for the optimisation of optical devices and the 3D printing process of plastic components as well as for predictive maintenance through digital twins. For this purpose, the VIPO team is developing what is known as a field correlation model (FCM), which takes into account various parameters that play a role at the beginning and end of a simulation process.